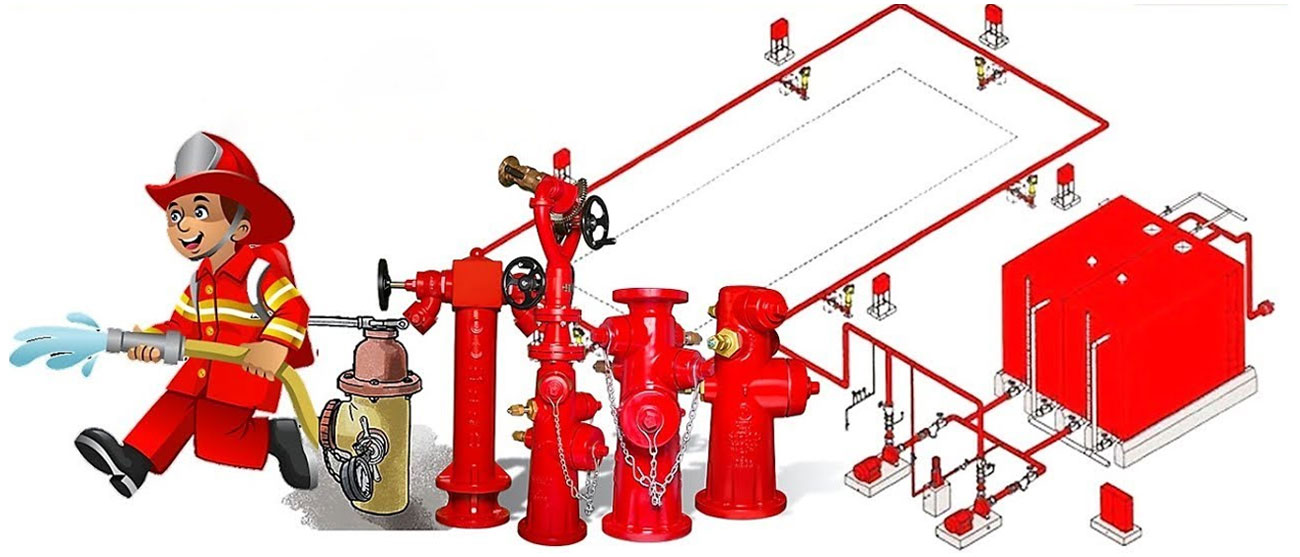

Components of a Fire Hydrant System

A Fire Hydrant System is made up of several critical components that work together to provide an effective firefighting solution. Each part plays a vital role in ensuring a reliable and continuous supply of water for fire suppression.

1. Fire Water Pump

The fire water pump is the heart of the fire hydrant system. It provides the necessary pressure to deliver water through the hydrant network. These pumps are usually:

- Electric Motor-Driven Pumps – Standard option for continuous operation.

- Diesel Engine-Driven Pumps – Backup pumps for reliability in case of power failure.

- Jockey Pumps – Maintain pressure in the system and prevent fluctuations.

2. Underground & Overground Piping Network

A system of pipes that transports water from the source (reservoir or tank) to different fire hydrants. The piping is categorized as:

- Underground Piping – Main water supply lines, protected from environmental damage.

- Above-Ground Piping – Connects to hydrants, valves, and hose reels for easy accessibility.

- High-Pressure Pipes – Designed to withstand strong water flow during firefighting.

3. Fire Hydrants (Landing Valves / Standposts)

Fire hydrants are the outlets that provide water access for firefighters. These can be:

- Wet Hydrants – Always connected to a pressurized water source, ready for immediate use.

- Dry Hydrants – Used in cold regions where water could freeze inside the pipes; water is supplied only when needed.

4. Hose Reels & Nozzles

Hose reels are flexible, high-pressure water hoses with a nozzle at the end. They allow firefighters to aim and control the water flow effectively.

- First-Aid Hose Reels – For initial response to small fires.

- Fire Hoses (Canvas or Rubber Lined) – Used for large-scale fire suppression.

- Branch Pipes & Nozzles – Regulate the direction and pressure of water discharge.

5. Water Storage Tank

A dedicated water storage tank ensures an uninterrupted water supply for the system.

- Above-Ground Tanks – Typically found in large commercial or industrial areas.

- Underground Tanks – Provide space-efficient water storage for fire emergencies.

- Capacity – Depends on the risk assessment and building size, ensuring an adequate water reserve.

6. Control Valves & Isolation Valves

These valves regulate water flow, ensuring proper operation and maintenance.

- Gate Valves – Used for shutting off water supply when required.

- Butterfly Valves – Quick-action valves for controlling water distribution.

- Pressure Reducing Valves (PRV) – Maintain optimal water pressure and prevent damage to hoses or equipment.

7. Fire Brigade Connections

These external inlets allow fire department personnel to connect their hoses and pump additional water into the hydrant system when required.

- Suction Inlets – Help in refilling the water storage tank.

- Delivery Outlets – Provide access for external firefighting units.

Pressure Gauges & Flow Meters

These monitoring devices ensure that the hydrant system is functioning correctly.

- Pressure Gauges – Indicate water pressure levels in the pipes.

- Flow Meters – Measure the amount of water being supplied for firefighting operations.

9. Post Indicator Valve (PIV)

A specialized valve used to control water flow from the main supply. It is positioned above ground with a visible indicator showing whether the valve is open or closed.

10. Fire Alarm & Detection System (Optional Integration)

Modern fire hydrant systems can be integrated with:

- Smoke & Heat Detectors – Detect early signs of fire and activate the hydrant system.

- Alarm Panels – Notify emergency responders when the system is in use.

- Sprinkler System Connection – Works alongside automatic sprinklers for enhanced fire protection.